From food to toiletries and drinks to electronics, packaging is everywhere. It makes a huge impact on the planet with countless resources used in the creation of products often designed to be discarded. Additionally, a large portion of that packaging used to protect consumer goods is manufactured from plastic and is never recycled.

To put our packaging use into context, in 2018 the Environmental Protection Agency estimated 82,220 million tons of packaging were being generated annually with 44,330 million tons recycled.

To put our packaging use into context, in 2018 the Environmental Protection Agency estimated 82,220 million tons of packaging were being generated annually with 44,330 million tons recycled.

There is not a simple solution to reducing the amount of packaging that’s incinerated or ends up in landfill in our consumer-oriented world. In fact, debate continues over what the best approach to truly sustainable packing really is. Today, the best bet is for manufacturers to use materials that are either reusable or recyclable, but is one solution better than the other?

Packaging that’s designed to be used again, recycled efficiently, or is biodegradable helps close the loop, creating fewer waste materials that end up in landfill or that are incinerated in waste-to-energy facilities. However, each route has its pros and cons, and for both manufacturers and consumers, choosing the best is not easy.

Reusable vs Disposable Packaging

On the surface, reusable packaging seems like an easy win, cycling packaging products to be used again for the same purpose. But, this approach is not always practical and certain goods are unsuitable for this type of packaging.

On the surface, reusable packaging seems like an easy win, cycling packaging products to be used again for the same purpose. But, this approach is not always practical and certain goods are unsuitable for this type of packaging.

Additionally, reusable packaging takes significantly more resources and money to manufacture, and the bottom line is no packaging lasts forever. The durability required in reusable packaging may also mean it cannot be recycled when it does reach the end of its life.

Disposable packaging, on the other hand, has something of a bad reputation, but it doesn’t have to be that way. While single-use plastics are inherently destructive, biodegradable packaging made from sustainable or recycled sources is usually cheap, easy to recycle, and can be integrated back into the loop easily through composting.

The question of which is better is not an easy one to answer when we look towards a zero-waste or truly sustainable future. Here, we dive a little deeper into the issues surrounding both approaches and what the future of packaging might look like.

Source: zerowaste.com

What is Reusable Packaging?

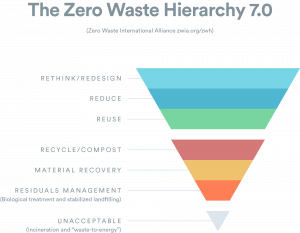

According to the zero-waste hierarchy, the best option is to re-think or redesign packaging in order to reduce the amount used—or eliminate it all together. In many cases, this simply isn’t possible. Some products require packaging to keep them in good condition, to contain liquids or moving parts, or to protect them from tampering.

In cases where packaging is essential, the next-best option is to find ways to reuse materials so that they’re not thrown away after a single use. This means more than simply reusing a jar at home after you have eaten the contents, and the concept of reusable packaging must include increased responsibility from manufacturers and distributors.

Truly reusable packaging must return to the manufacturer or distributor to be used in the same, or similar, way. For example, in some parts of the US, paying a deposit on a glass water, soda, or beer bottle is common practice, and the consumer receives the deposit back when the bottle is returned to the retailer. After this, glass bottles are returned to the producer who then cleans and refills them.

What is Disposable Packaging?

According to the zero-waste hierarchy, the next-best option after reusing is to compost or recycle our packaging. This is a less preferable option because, unlike reusing products, recycling and composting require waste to be transported and processed. This consumes energy and has an impact on the environment.

Disposable packaging generally has a big advantage over reusable packaging in that it takes significantly less energy and resources to manufacture. Single-use plastics, paper and card, and even mixed material products such as Tetra packs can be produced relatively cheaply and this is among the reasons for their ubiquity today.

Disposable packaging generally has a big advantage over reusable packaging in that it takes significantly less energy and resources to manufacture. Single-use plastics, paper and card, and even mixed material products such as Tetra packs can be produced relatively cheaply and this is among the reasons for their ubiquity today.

That said, many of the disposable materials used to make packaging are not biodegradable or recyclable. As a result, they end up in landfill or being incinerated. Finding alternative materials can help manufacturers to maintain the quality and convenience of their packaging while dramatically reducing its impact on the environment.

There are currently a number of sustainable packaging alternatives being developed and put into use around the world. Compostable packaging can now be made relatively easily using natural, disposable products like cellulose and mycelium. These can be shaped to serve a variety of purposes and used for food packaging or to protect furniture and other shop-bought products.

Source: wyss.harvard.edu

Cornstarch is another popular material for manufacturers who want to replace disposable items with compostable ones. It can be used to make loose-fill packaging or molded into rigid forms. While this type of material isn’t without its environmental problems, cornstarch can be composted once used and can help to reduce the amount of waste produced by packaging.

Harvard University’s Wyss Institute has also created “shrilk,” a low-cost, clear ‘bioplastic’ that’s completely compostable. Shrilk is made of chitosan, a material that’s derived from shrimp shells and a silk protein. It can be used to make film or rigid shapes, making it ideal for packaging.

The Future of Packaging

The reality is the future of packaging is likely to include both reusable and disposable variations, with both meeting the various demands of specific products and goods. It is possible to improve both with a focus on a more sustainable future.

The best way to drive innovation in packaging systems is for customers to demand compostable and reusable goods in place of single-use products. In the debate of reusable products versus products that are disposable, choosing sustainable options, refilling wherever possible, and making full use of available composting or recycling programs will help to direct manufacturers and encourage the use of more environmentally-friendly packaging.

Consumer Trends and Manufacturer Needs

Reusable packaging is already being developed to meet a new consumer culture that is beginning to value sustainability over convenience. One such company based in the US is LOOP, partnering with numerous companies including Procter & Gamble, Nestlé, PepsiCo, Unilever, and The Body Shop.

LOOP manufactures reusable packaging, but more than that, it acts as a delivery service for goods, distributing some of the world’s favorite products in reusable containers. Once the products are finished, the user packs them in a tote and waits for a delivery service to collect them. After this, the containers are sterilized using medical-grade techniques and refilled again.

Many people believe that this type of partnership is only the beginning of the reusable packaging story, and as consumer trends begin to align further with manufacturer needs there is hope that partnerships like those offered by LOOP will become more mainstream.

Composting and Waste Management for Disposable Packaging.

In the framework of disposable packaging systems, as well as manufacturing compostable and recyclable packaging, we also need to find effective solutions for dealing with this waste once it’s been generated. Currently, most disposable products are thrown away with little thought from the consumer and little care from the manufacturer.

Without the introduction of more efficient and cost-effective collection and composting programs, or the expansion of existing recycling provisions, people are unlikely to change their habits. As a result, it’s likely that compostable and recyclable materials will end up in the trash. Additionally, manufacturers must find more sustainable materials that are easily composted and recycled if they wish to rely on disposable packaging in the future.

For more information on the future of packaging and how zero-waste systems can help your business reduce waste, subscribe to zerowaste.com or contact one of our TRUE Advisors today.